The Advantages and Disadvantages of Plastic Toilet Brushes and Resin Toilet Brushes

In the realm of sanitation products, toilet brushes play a crucial role in maintaining hygiene. Among the various materials available, plastic and resin are two prominent options. This essay examines the advantages and disadvantages of plastic toilet brushes and resin toilet brushes from the perspectives of bulk procurement and sales, daily usage, surface finish, and minimum order quantities.

Bulk Procurement and Sales

When considering bulk procurement, plastic toilet brushes often emerge as the more economical choice. Their lower production costs facilitate competitive pricing, making them attractive for wholesalers and retailers. In contrast, resin toilet brushes, while generally more expensive, can command higher retail prices due to their perceived durability and aesth etic appeal. This factor may influence purchasing decisions in markets where consumers prioritize quality and design over cost.

Daily Usage

In terms of daily usage, plastic toilet brushes present certain practical advantages. They are lightweight and easy to handle, which can enhance user experience. However, they may not be as durable as resin brushes, which are known for their resilience and longevity. Resin brushes are less prone to wear and tear, making them a preferable option for consumers seeking a long-term investment. Nonetheless, the maintenance of both types requires regular cleaning to prevent the buildup of bacteria.

![]()

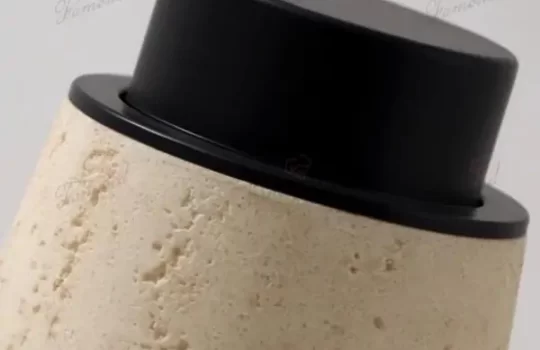

Surface Finish

The surface finish of toilet brushes is another critical consideration. Plastic brushes typically feature a smooth finish that is easy to clean but may lack the aesthetic appeal of resin brushes, which often boast a more sophisticated and polished appearance. The visual aspect of resin brushes can elevate the overall decor of a bathroom, making them a popular choice among consumers who value design.

Minimum Order Quantities

Lastly, minimum order quantities (MOQs) play a significant role in procurement strategies. resin toilet brushes generally have lower MOQs, making them accessible for smaller businesses or startups. Conversely, plastic toilet brushes may require higher MOQs due to their manufacturing processes, potentially limiting options for smaller retailers. This factor can influence the decision-making process for businesses when considering inventory management and financial investment.

In summary, both plastic and resin toilet brushes possess distinct advantages and disadvantages that impact their procurement, sales, and daily usage. While plastic brushes offer cost-effectiveness and ease of handling, resin brushes provide durability and aesthetic appeal. Ultimately, the choice between the two will depend on the specific needs and priorities of consumers and businesses alike.