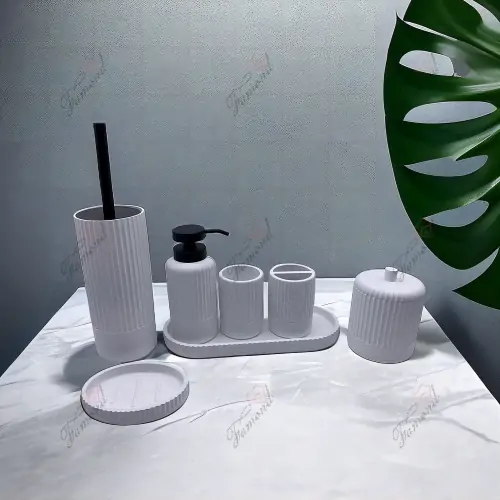

Polyresin Bathroom Accessories Set Produce Process -FM8700.5006 New Design- From Idea to Real Prodcut

Producing polyresin bathroom products involves a multi-step process that combines the properties of resin and other materials to create durable and aesthetically pleasing items. Here’s an overview of the typical production process for polyresin bathroom products:

- Design and Prototyping:The first step is to create a design for the bathroom product. This can be done using computer-aided design (CAD) software or traditional hand sketching. Once the design is finalized, a prototype is created to test the functionality and appearance of the product.

- Mold Making:After the prototype is approved, a mold is created based on the design. Molds are typically made from silicone or other materials that can withstand the resin casting process. The mold will have the exact negative shape of the final product.

3.Preparing the Resin:Polyresin is a combination of liquid resin and a powdered filler material (such as calcium carbonate) that gives the product its texture and weight. The ratio of resin to filler is crucial for achieving the desired properties. Pigments can also be added at this stage to give the product its color.

4.Casting the Resin:The prepared resin is poured into the mold. The mold is then carefully sealed to prevent any leaks during the curing process. The mold is rotated or vibrated to remove any air bubbles and ensure that the resin fills all the intricate details of the mold.

5.Curing:The filled mold is placed in an oven or allowed to cure at room temperature. The curing process involves a chemical reaction that solidifies the liquid resin into a solid form. The curing time can vary depending on the size and complexity of the product.

6.Demolding:Once the resin has fully cured and hardened, the mold is opened to reveal the polyresin product. The product is carefully removed from the mold to avoid any damage.

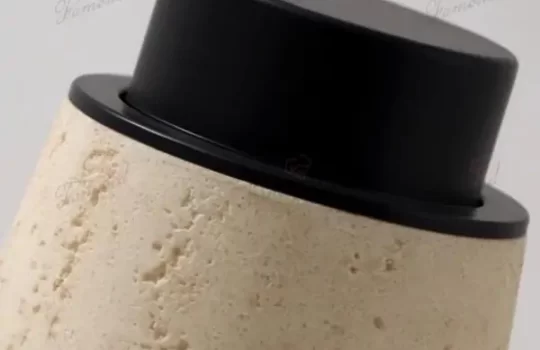

7.Trimming and Finishing:After demolding, excess material and rough edges are trimmed and sanded to achieve a smooth and refined appearance. This step ensures that the final product meets the design specifications and quality standards.

8.Quality Control:Each polyresin bathroom product goes through a quality control process to check for any defects, imperfections, or color inconsistencies. Any flawed products are rejected or recycled.

9.Surface Treatment and Assembly:Depending on the design, the product may undergo additional surface treatments, such as painting, glazing, or applying a protective coating. If the product consists of multiple parts, they are assembled together during this stage.

10.Packaging:Finally, the finished polyresin bathroom products are packaged and prepared for distribution and sale.

It’s important to note that variations in the production process may exist depending on the specific type of polyresin bathroom product being manufactured and the manufacturing facilities. Additionally, safety measures and environmental considerations are essential throughout the process to ensure safe handling and disposal of materials.