About

Who is FAMOND

Famond is an international trading company specializing in the design and production of resin, cement, and diatomite products. Our product line covers a variety of bathroom accessories, home decor items, and storage solutions, all aimed at providing modern homes with both practical and aesthetically pleasing household items.

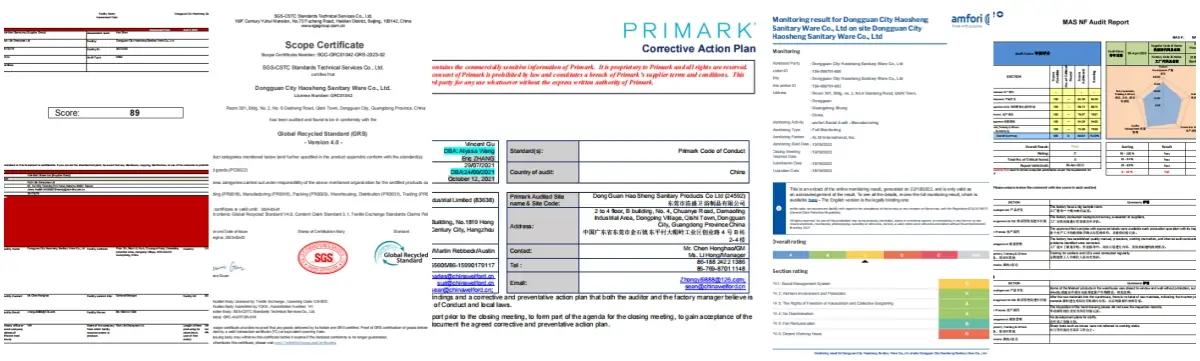

What Factory Audit Has FAMOND Passed

Customer-Specific Audits:Audits conducted according to the specific requirements of major clients to ensure compliance with their quality and safety standards.

Famond's Workshop

About Material

What are the key pros and cons of resin products?

- Pros: Lightweight, durable, versatile design options, cost-effective, and water-resistant.

- Cons: Susceptible to scratches, poor heat resistance, and can fade with UV exposure.

Resin products are lightweight, durable, and versatile, ideal for molding into various designs. They are cost-effective and water-resistant, perfect for bathrooms. However, they can be susceptible to scratches, have poor heat resistance, and may fade when exposed to UV light.

What are the pros and cons of diatomite?

- Pros: Natural, non-toxic, absorbs humidity, regulates air quality, and sound-insulating.

- Cons: May be more expensive, requires careful maintenance, and limited color options.

Diatomite, or diatomaceous earth, is valued for its natural and non-toxic properties, ability to absorb excess humidity, help regulate indoor air quality, and provide sound insulation. However, it can be more costly than other materials, requires specific care to maintain its benefits, and often comes with fewer color choices.

What are the key advantages and disadvantages of cement / concrete?

- Advantages: Durable, fire-resistant, resilient to weather, cost-effective, and moldable.

- Disadvantages: Heavy, lacks insulation, long curing time, and may need finishing for aesthetics.

Cement / Concrete’s strengths include durability, fire resistance, weather resilience, cost-effectiveness, and moldability. However, it is heavy, lacks insulation properties, has a long curing time, and may require finishing for aesthetic appeal.

Can Resin, Cement, and Diatomite Be Made Recyclable?

Resin, cement, and diatomite can be made more environmentally friendly and recyclable through various methods and approaches:

1.Resin:

- Biodegradable Resins: Some resins can be engineered to be biodegradable, meaning they break down naturally over time without causing harm to the environment.

- Recycling Processes: Certain types of resins can be recycled through mechanical or chemical processes. Mechanical recycling involves grinding the resin into smaller pieces and reusing them in new products. Chemical recycling breaks down the resin into its base components, which can then be used to make new resin products.

- Compostable Resins: Some resins are designed to be compostable, allowing them to decompose in industrial composting facilities.

2.Cement:

- Green Cement: There are alternative cements, such as geopolymer cement, which have a lower carbon footprint and can be more sustainable. Geopolymer cement uses industrial waste products like fly ash and slag, reducing the need for traditional cement production.

- Recycled Aggregate: Concrete can be crushed and reused as aggregate in new concrete mixes, extending the lifecycle of the material.

- Fly Ash and Slag: Using fly ash and ground granulated blast furnace slag (GGBFS) as partial replacements for Portland cement can reduce the overall environmental impact.

3.Diatomite:

- Natural Material: Diatomite is a naturally occurring material that is biodegradable and non-toxic. It can be reused or repurposed in various applications.

- Composting: Diatomite can often be composted after use, returning it to the soil without causing pollution.

- Sustainable Extraction: Ensuring sustainable extraction and processing methods can minimize the environmental impact of diatomite production.

Key Points:

- Material Design: Developing materials that are inherently easier to recycle or decompose.

- Recycling Infrastructure: Establishing robust recycling infrastructure to support the collection and processing of these materials.

- Sustainable Practices: Implementing sustainable practices throughout the entire lifecycle of the product, from production to disposal.

By adopting these approaches, resin, cement, and diatomite products can be made more environmentally friendly and recyclable, contributing to a more sustainable future.

How to clean and maintain resin products?

- Regular Cleaning: Use a soft cloth or sponge with mild soap and water.

- Avoid Abrasives: Do not use abrasive cleaners or tools to prevent scratches.

- Polishing: Apply furniture polish or wax with a soft cloth for a shiny finish.

- Stain Removal: Use a gentle stain remover or a baking soda and water mixture.

- Rinsing: Rinse with clean water after removing stains.

- Sunlight Protection: Keep away from direct sunlight to prevent fading.

- Heat Protection: Avoid exposing to extreme heat.

- Careful Handling: Handle with care to avoid scratches and chips.

How to clean and maintain Diatomite products?

- Daily Dusting: Regularly dust the surface with a soft, dry cloth to remove loose dirt.

- Gentle Cleaning: For deeper cleaning, use a mild detergent mixed with water. Apply the solution with a soft sponge, gently wiping the surface without saturating it.

- Rinsing: Rinse with clean water and pat dry immediately with a soft towel to prevent water spots.

- Avoid Harsh Chemicals: Do not use abrasive cleaners or harsh chemicals, as these can damage the natural properties of diatomite.

- Sunlight and Ventilation: Place diatomite products in a well-ventilated area, as they benefit from air circulation and can naturally absorb moisture. However, avoid direct sunlight to prevent fading.

These steps will help keep your diatomite products clean and extend their lifespan.

How to clean and maintain cement products?

- Daily Cleaning: Wipe down surfaces with a damp cloth or sponge. For tougher dirt, use a mild detergent mixed with water.

- Deep Cleaning: For stains or buildup, create a paste with baking soda and water. Apply the paste, let it sit for a few minutes, then scrub gently with a soft-bristled brush before rinsing.

- Sealing: To protect against stains and water damage, apply a sealant specifically designed for cement. This helps keep the surface looking new and reduces maintenance.

- Avoid Harsh Chemicals: Do not use acidic or abrasive cleaners as they can etch or dull the surface of the cement.

- Regular Inspection: Check for any signs of wear or damage and address issues promptly to prevent further deterioration.

By adhering to these maintenance tips, you can extend the life and appearance of your cement products.

What is the Differences Between GRS Certification for 20-50% and Over 50% Recycled Content

The Global Recycled Standard (GRS) certifies products based on the proportion of recycled materials and sustainable production processes. Here are the key differences between 20-50% and over 50% recycled content:

20%-50% Recycled Content

1.Certification Level:

- Products with 20%-50% recycled materials can be GRS certified.

- Labels may indicate “Made with Recycled Materials.”

2.Labeling Requirements:

- Products can mention the presence of recycled materials on packaging or labels.

3.Production Process:

- Basic GRS requirements for chemical management, social responsibility, and environmental management are followed.

- Some flexibility in requirements.

Over 50% Recycled Content

1.Certification Level:

- Products with over 50% recycled materials achieve a higher GRS certification.

- Considered more sustainable and environmentally friendly.

2.Labeling Requirements:

- Products can prominently label themselves as “Recycled” or “100% Recycled.”

- GRS logos can be more prominent.

3.Production Process:

- Stricter standards for chemical management, social responsibility, and environmental management.

- Higher requirements for supply chain transparency and sustainability.

Summary

- 20%-50% Recycled Content: Can achieve GRS certification with less strict labeling and production requirements.

- Over 50% Recycled Content: Achieves a higher GRS certification with more prominent labeling and stricter production standards.

These distinctions help consumers make more informed purchasing decisions based on sustainability and environmental impact.

Custom Solution Inquiry

Custom solutions tailored to your needs. Request now for precision quote.