Unsaturated polyester resins (UPR) are crucial thermosetting resins known for their excellent mechanical properties, chemical resistance, and ease of processing. This article provides an overview of the formation principles, key components, and diverse applications of UPR in everyday life.

Formation Principle UPRs are synthesized through the condensation polymerization of saturated dicarboxylic acids or their anhydrides (e.g., maleic anhydride), unsaturated dicarboxylic acids (such as fumaric acid), and polyols (like propylene glycol or neopentyl glycol). In this process, catalyzed reactions form linear prepolymers with double bonds, making them “unsaturated.”

Key Components

Saturated Dicarboxylic Acids/Anhydrides: Enhance cross-linking density and hardness.

Unsaturated Dicarboxylic Acids: Provide cross-linking capability.

Polyols: Adjust flexibility and viscosity.

Crosslinking Agents: Typically styrene, forming a three-dimensional network.

Initiators: Such as benzoyl peroxide, initiating curing.

Accelerators: Like cobalt naphthenate, speeding up curing.

Inhibitors: Maintain stability during storage.

Everyday Applications

Artistic Crafts :UPRs are favored for crafts due to their fluidity and high-strength post-curing. They can be used for sculptures, decorative items, and models, offering customizable colors and designs.

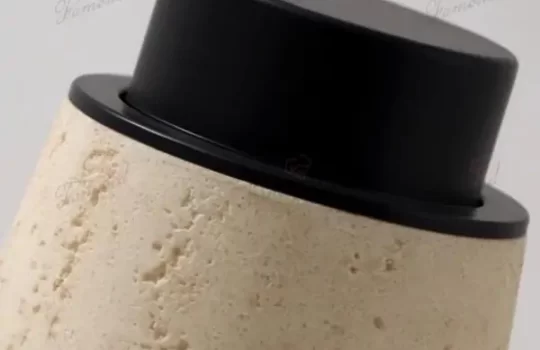

Outdoor Decor: For outdoor decor like planters, fountains, and sculptures, UPRs offer durability and weather resistance, allowing for custom designs that withstand external elements.

Bathroom Fixtures: UPRs create waterproof, easy-to-clean bathroom fixtures such as sinks, bathtubs, and shower bases. Their smooth surface and modern designs add aesthetic appeal.

Home Décor: From tabletop decorations to wall art, UPRs enable designers to craft unique home decor pieces that are lightweight, easy to transport, and install.

Additional Uses Beyond these areas, UPRs find application in composites, construction, electrical insulation, coatings, and paints, contributing to sectors like aerospace, automotive, marine, sports equipment, and more.

UPRs play a significant role in both industrial and domestic settings, leveraging their multiple advantages to meet various needs. As technology advances, the future will likely see even broader and innovative applications for these versatile materials.